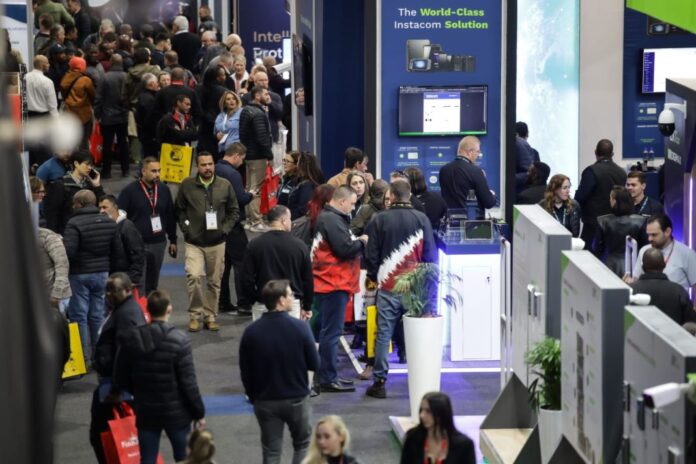

As the demand for smarter, more resilient security solutions continues to grow, Securex South Africa 2025 is the must-attend event for professionals across the security and risk management sectors. Taking place from 3 to 5 June 2025 at Gallagher Convention Centre, the expo brings together leading security innovators, superior technology, and unmissable live demonstrations.

“Co-located with A-OSH EXPO, Facilities Management Expo, and Firexpo, Securex South Africa offers a 360° view of security, occupational safety & health, facilities management, and fire protection solutions — all in one venue,” says Mark Anderson, Portfolio Director at Specialised Exhibitions — a division of Montgomery Group.

Some examples of the security solutions on display include:

- The SIMcontrol (Hall 2, Stand C17) platform, which enables seamless, cost-effective management of critical device SIM cards across all major mobile networks, making it ideal for CCTV, alarm systems, access control, and guard tracking devices.

- Experience the Fog Bandit (Hall 2, Stand A10) in action. Watch as the system engulfs a space in seconds, leaving criminals completely blind and disoriented.

- ServCraft (Hall 2, Stand F34) business management software is the ideal choice for security installation, repair and maintenance businesses. The company recently launched an industry-first initiative — ServCraft Mastery, an educational platform for security business owners to bring them content, curriculum and coaching to grow their business.

- The Turnstar (Hall 2, Stand B08) Velocity Raptor is designed to enhance traffic flow and security, offering high-speed operation, to minimise delays for vehicles passing through. The barrier has an optic LED barrier arm for improved visibility, especially in low-light or poor weather conditions.

- YeboTech (Hall, Stand C13a) specialises in smart key and locking solutions. Unlike traditional mechanical locks, YeboTech’s solutions enhance security by eliminating the risks of lost or duplicated keys, while providing full control over access using the advanced software management platform for remote configuration and monitoring.

- Amongst other solutions, Hikvision (Hall 2, Stand A01) will showcase its Prime Pass Series speed gates. This new series integrates advanced technologies such as direct Time-of-Flight (dToF) sensors and biometric recognition, combining record acquisition, verification, and control into a single cohesive system to streamline installation and enhance the passing experience.

- Arteco (Hall 2, Stand D09) is redefining video surveillance with the latest advancements in uSee, its VSaaS solution. The new forensics search engine leverages metadata to instantly locate people, belongings, and vehicles, drastically cutting down search times for faster security responses.

- iWalkie (Hall 2, Stand B15), part of the RTS Group, specialises in GSM radios for users with more diverse needs. The iWalkie mobile radio features 4G+ network support, GPS tracking, individual calling, duplex calling, panic button and a remote programmable function.

- PIMA Electronic Systems (Hall 2, Stand D03) offers a comprehensive portfolio of hardwired, hybrid, and wireless alarm systems suitable for residential, commercial, and industrial applications. PIMA offers a cloud-based application for remote monitoring and control, enhancing user convenience and security management.

- KYR (Hall 2, Stand C22) offers an array of advanced systems, including Hanwha CCTV surveillance, Intercall nurse call systems, Eaton fire alarm systems, FBT public address systems, RBH access control, and Bodet master clock systems.

- InQuest Forensic Services (Hall 2, Stand C11b) specialises in forensic psychophysiology (polygraphy) as an investigative tool to assist companies and individuals with uncovering the truth in various matters. The company also conducts a range of background checks to support its clients in their pursuit of truth.

- New Glory (Hall 2, Stand F21) will introduce its tactical anti-ballistic glasses and goggles. Engineered to exceed the US Military MIL-PRF-32432 standards, the eyewear features the exclusive ZeroFog™ Technology, meaning the lenses stay clear even after 30 seconds of hot water exposure, guaranteeing unmatched anti-fog performance.

- The Docked Drone Solution from 24/7 Drone Force (Hall 2, Stand D14) utilises unmanned aircraft systems (UAS)/drones designed to conduct remote docking station operations. The drone-in-a-box solution takes off, lands, and recharges from a docking station automatically.

- Avior Labs (Hall 2, Stand F31) will showcase Elevation-G, a next-generation fixed-wing VTOL drone designed for advanced surveillance and security operations. With SilentFly™ technology for covert missions, a dual EO-IR stabilised camera, and real-time video streaming, it delivers high-performance intelligence gathering with exceptional range and endurance. Elevation-G is ideal for defence, security, and critical infrastructure monitoring.

- Nemtek (Link Node, Stand LN6) will demo its newly enhanced FG7C+ Fence Controller, now with an advanced software upgrade that connects all Nemtek devices, and the Nemtek Connect Portal — a web-based platform for comprehensive site management.

Action-packed visitor attractions

Anderson says that visitors can experience live demonstrations, expert-led competitions, and interactive showcases throughout the event:

-

- SAIDSA Techman Competition — Watch South Africa’s top security technicians go head-to-head as they battle for top honours in this high-stakes skills contest.

- K9 Demonstrations — See highly trained security dogs in action as they showcase their expertise in detection, patrol, and protection techniques.

- Drone Demonstration Area — Get up close with the latest in aerial security surveillance as drones take centre stage, demonstrating their capabilities in perimeter monitoring and rapid response.

- OSPA Awards — The Outstanding Security Performance Awards (OSPAs) recognise excellence across the security industry, celebrating businesses and individuals who go above and beyond in safeguarding people and assets.

“And we mustn’t overlook the free-to-attend Securex Seminar Theatre, in partnership with SMART Security Solutions. Knowledge is power, and the seminar sessions deliver expert insights into the latest security trends, technologies, and challenges,” says Anderson.

Some of the topics visitors can look forward to include:

- The real impact of AI on security.

- Remote monitoring with AI.

- Perimeter security for 2025.

- The new CCTV draft law.

- Cybersecurity.

- Local innovation in security.

- Access control & visitor management.

- The future of guarding.

- Reasons to use a registered security company and service provider.

Industry body endorsement

“Securex South Africa is proudly supported by leading industry bodies, reinforcing its status as the region’s premier security event. We have developed long and lasting relationships with respected industry bodies that represent the individuals and organisations that come to Securex South Africa for their security solutions,” Anderson points out.

These include American Society for Industrial Security — South African Chapter (ASIS International), Electronic Security Distributors Association (ESDA), Fire Protection Association of Southern Africa (FPASA), National Bargaining Council — Private Security Sector, Outstanding Security Performance Awards (OSPA), Private Security Industry Regulation Act (PSiRA), South African Intruder Detection Services Association (SAIDSA), and South African Security Association (SASA).

Entry into Securex South Africa and the co-located shows is free. To find out more about Securex South Africa, and to pre-register, visit the expo’s website at https://securex.co.za/

Organisations wishing to exhibit at Securex South Africa 2025 can contact the Securex South Africa team on zelda.jordaan@montgomerygroup.com or johan.vanheerden@montgomerygroup.com to book a space or capitalise on a sponsorship opportunity.

Water security isn’t just a government issue, it’s everyone’s responsibility. The choices we make today about training and education will determine South Africa’s water future. Industry leaders must invest in skills development and innovation, universities and TVET colleges should collaborate with EWSETA to create cutting-edge training programmes, and government must prioritise workforce training to improve service delivery.

Water security isn’t just a government issue, it’s everyone’s responsibility. The choices we make today about training and education will determine South Africa’s water future. Industry leaders must invest in skills development and innovation, universities and TVET colleges should collaborate with EWSETA to create cutting-edge training programmes, and government must prioritise workforce training to improve service delivery.